What is Catheter Tipping?

Catheter tipping, also known as end forming, is the process of shaping the end of a thermoplastic tube using a thermally conductive mold. For medical device manufacturers, there are several common methods for application of energy to the conducive mold including:

- Hot air processing

- Induction heating

- Heat shrink applications (including hot air or laser technologies)

Hot air processing

Hot air processing is the least expensive equipment option, but typically requires secondary trimming processes as energy through convection and conduction of the hot air spreads across a wide area of the mold. Glass molds from Farlow’s scientific (link) are typically utilized to allow the operator to view the tipping process. Glass has an advantage of being very smooth to limit material sticking and eliminate need for mold release lubricants. Simple shapes and initial prototypes in low volumes are good fits for this technology.

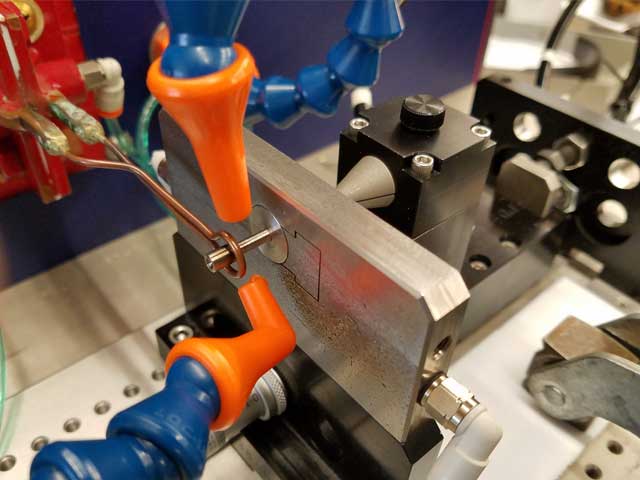

Induction heating

Induction heating (or RF Tip Forming) is a highly effective non-contact method of heating a metal mold. This is the most reliable technology for catheter tipping due to focused energy application, lack of operator interaction and ability to create complex tooling designs. Tooling is made from magnetic and electrically resistive materials such as tool steels and 400 Series stainless. Nickel molds allow for complex shapes which can not be machined using typical EDM or CNC machining equipment however they are not as magnetic, so they transfer heat less efficiently. Induction heating allows for the fastest cycle times due to the ability to rapidly heat the mold with RF energy and quickly quench materials using cool air or water.

Machine Solutions features two types of induction heating (RF Tip Forming) technologies through the acquisition of our industry leading brands Vante and PlasticWeld Systems.

PlasticWeld RF Tipping Machines features a free-floating coil. This technology requires the operator to accurately position the mold within the RF coil but provides a lower cost solution for customers who require a high quantity of mold designs. This technology excels for larger sizes of tubes including long tapered dilators, flanges and flares.

Vante RF Tip Forming technology incorporates the RF coil and a thermocouple within a mold “Cartridge” to allow for fast tooling swaps and ensures the RF energy is focused on the same section of the mold for each run. Due its proprietary thermal management technology, Vante systems excel for smaller sizes of tubes and butt weld / braid to non-braid welding. This technology can provide the fastest cycle times possible, and systems are configured to span all production capacity requirements.

Heat shrink applications

It is also possible to utilize heat shrink tubing in combination with hot air or laser energy to form the thermoplastic tip into their desired shape.

For initial prototypes and some angiographic catheters with large wall thicknesses, heat shrink in combination with hot air energy are good technology fits for simple rounding of the tip. This is a manual process that can be executed by skilled operators.

Balloon catheter tips are commonly shaped during the distal bonding of the balloon and/or soft tip attachment. Utilizing polyolefin heat shrink the laser is traversed distally to flow the tip material to a smaller size. OD is only controlled by the heat shrink. This process typically requires a secondary cutting process to cut the tip to the desired length.

Considerations for which technology to specify:

To select the best technology for your situation, you need to consider several points:

Procurement costs

The initial purchase price of the equipment is only part of the true procurement cost. Installation and site preparation costs must also be considered, as well as any IOPQ requirements, training and documentation costs. A higher-priced system may well have features and capabilities that REDUCE post-delivery costs, thus making the total acquisition cost lower.

Operating costs

Total cycle time including product handling, tooling alignment, heating/cooling times and secondary process can have a major impact on operating costs. Processes that utilize secondary processing aids like cutting or heat shrink removal have associated handling and disposal costs that should be considered. Output of the machines, such as excessive hot air, may increase your HVAC costs. Consider the type of utilities, maintenance and floor space the system will require. Systems with smaller overall footprints will enable more efficient use of your cleanroom space.

Scalability

When adding production capacity, consider whether you will be adding more machines – and therefore more operators – or procure equipment with capability to output higher capacity. When considering higher capacity machines, will they have different technologies that complicate the validation effort?

Technical support capabilities of the equipment manufacturer

Most experienced users of tip forming machines know post-purchase technical support can help alleviate long delays in troubleshooting efforts. Equipment manufacturers who have focused support with sufficient bandwidth to provide rapid response will help prevent loss of manufacturing time.

Sustainability of the equipment

Consider the business health of your equipment supplier. A larger company with a stable business history and demonstrable plan for growth and innovation will have the lowest risk to remain a viable supplier in the future.

Turnkey Solution

Die design and process development experience can prove equally as important as technology selection. Ensure your supplier can advise recommended process strategies, design tolerances and geometries, material selection and other critical inputs to ensure a robust manufacturing process and risk mitigation.